Since the July 2022 inauguration of our 30,000 square foot state-of-the-art Lithium Technical Development Center (LiTDC) in Reno, Nevada, we have been producing battery-quality lithium carbonate samples from Thacker Pass ore.

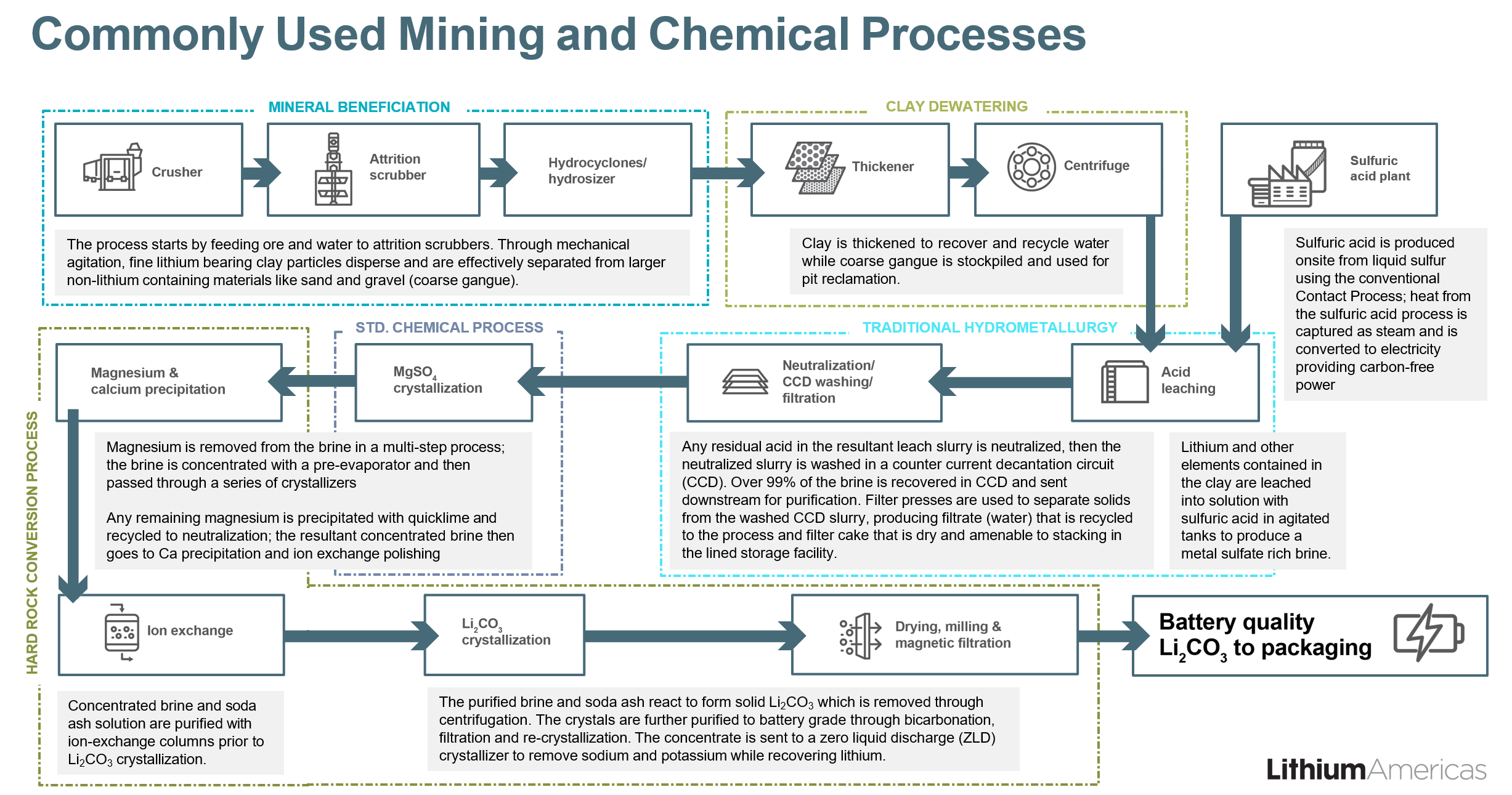

The Thacker Pass flowsheet is a unique end-to-end combination of commonly used mining and standard chemical unit operations. These processes have been proven for decades in traditional phosphate, mining, and hydrometallurgy industries.

The LiTDC houses a full-scale hydrocyclone to help mitigate scaling up issues (photo shown below).

Following the magnesium sulfate crystallization process, the intermediary product is lithium sulfate, which is the same lithium chemical produced following conversion of hard rock lithium-bearing ore to lithium chemicals. The lithium sulfate is then purified and processed to battery-quality lithium carbonate the same way it's currently being done globally.

The LiTDC is unique in the U.S. and will serve as an economic driver for Nevada's growing battery supply chain.

Watch this video (opens in new window) to see the steps in our processing flowsheet.

The LiTDC houses a full-scale hydrocyclone to help mitigate scaling up issues.

The LiTDC houses a full-scale hydrocyclone to help mitigate scaling up issues.