The Quinn pipeline is a 6.6-mile-long underground water pipeline that delivers water from our permitted production well in the Quinn River Basin to Thacker Pass. The water pipeline is an essential component of a water supply system that was commissioned in July 2023 to support Thacker Pass construction.

-

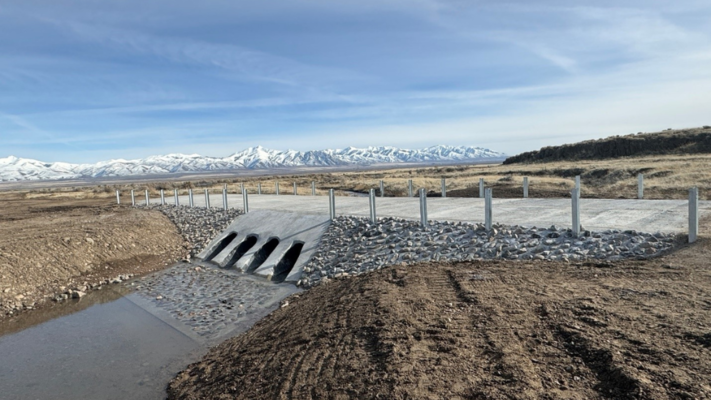

As part of our water pipeline project, we partnered with High Mark Construction to build concrete armor barriers to prevent erosion at two Crowley Creek crossings on our pipeline right-of-way in the Quinn Valley. Concrete has been placed on the creek sides, and concrete driveways have been installed across the tops of both crossings.

As part of our water pipeline project, we partnered with High Mark Construction to build concrete armor barriers to prevent erosion at two Crowley Creek crossings on our pipeline right-of-way in the Quinn Valley. Concrete has been placed on the creek sides, and concrete driveways have been installed across the tops of both crossings.

Per BLM standards with M3 Engineering and Technology, these concrete creek crossings are designed to survive projected 100-year storms, prevent erosion and preserve the original flow of water, while making it safer and more efficient to access the Quinn Valley wells.

-

The Quinn underground water pipeline is 6.6-miles-long and is an essential component of our water supply system to support construction. It delivers water from our permitted production well in the Quinn River Basin, to Thacker Pass.

The Quinn underground water pipeline is 6.6-miles-long and is an essential component of our water supply system to support construction. It delivers water from our permitted production well in the Quinn River Basin, to Thacker Pass.

-

Development of the pipeline was carried out safely and efficiently through a collaborative effort. M3 Engineering & Technology completed the engineering. EDG Inc. was instrumental in sourcing the necessary materials. The stainless-steel pipe fittings were fabricated by Great Basin Industrial and installed by High Mark Construction. NewFields provided quality control services and Bechtel oversaw quality assurance to ensure safety compliance.

Development of the pipeline was carried out safely and efficiently through a collaborative effort. M3 Engineering & Technology completed the engineering. EDG Inc. was instrumental in sourcing the necessary materials. The stainless-steel pipe fittings were fabricated by Great Basin Industrial and installed by High Mark Construction. NewFields provided quality control services and Bechtel oversaw quality assurance to ensure safety compliance.

-

The 24" diameter water pipeline is pictured, prior to being buried. The Quinn Pipeline infrastructure will continue to be upgraded to provide construction water necessary for dust control and compaction, as well as the forthcoming build of the processing plant.

The 24" diameter water pipeline is pictured, prior to being buried. The Quinn Pipeline infrastructure will continue to be upgraded to provide construction water necessary for dust control and compaction, as well as the forthcoming build of the processing plant.

-

An aerial photo illustrates a portion of the 6.6-mile-long Quinn underground water pipeline corridor, as well as the concrete armor barriers that were built to prevent erosion at two Crowley Creek crossings on our pipeline right-of-way in the Quinn Valley.

An aerial photo illustrates a portion of the 6.6-mile-long Quinn underground water pipeline corridor, as well as the concrete armor barriers that were built to prevent erosion at two Crowley Creek crossings on our pipeline right-of-way in the Quinn Valley.

-

The Quinn underground water pipeline delivers water from our permitted production well in the Quinn River Basin, to construction water ponds located near the future plant pad at Thacker Pass.

The Quinn underground water pipeline delivers water from our permitted production well in the Quinn River Basin, to construction water ponds located near the future plant pad at Thacker Pass.

-

The 24" diameter water pipeline has been buried and is now being prepared for reclamation. The area has been contoured and is awaiting seeding with native plant seeds, later this year.

The 24" diameter water pipeline has been buried and is now being prepared for reclamation. The area has been contoured and is awaiting seeding with native plant seeds, later this year.

The Quinn pipeline is a 6.6-mile-long underground water pipeline that delivers water from our permitted production well in the Quinn River Basin to Thacker Pass. The water pipeline is an essential component of a water supply system that was commissioned in July 2023 to support Thacker Pass construction.

Development of the pipeline was carried out safely and efficiently through a collaborative effort. M3 Engineering & Technology completed the engineering. EDG Inc. was instrumental in sourcing the necessary materials. The stainless-steel pipe fittings were fabricated by Great Basin Industrial and installed by High Mark Construction. NewFields provided quality control services and Bechtel oversaw quality assurance to ensure safety compliance.

THE ROLE OF THE PIPELINE FOR THACKER PASS

Two wells were drilled to provide water for construction and future production needs. The Quinn 1 Well, drilled to a depth of 565 feet below ground surface, is the current construction well. It was developed with a variable frequency drive (VFD) electric motor controller to manage power and water flow for the Quinn 1 Well pump. The Quinn 2 Well, drilled to a depth of 570 feet below ground surface, is a similar design, size and capacity as Quinn 1 and is planned to tie into the currently installed pipeline to support project operations and provide infrastructure redundancy.

WATER RIGHTS

Lithium Americas has received the State’s approval to convert approximately 3,600-acre feet annually (AFA) of water rights from farming and ranching operations in the Quinn Valley to the Thacker Pass project. An AFA of water is enough to cover one acre of land one foot deep. Only 2,850 AFA, or roughly the equivalent of four to five alfalfa pivots, will be used at Thacker Pass. The rest, 750 AFA, will remain in the aquifer, unused. That is due to a provision enforced by the Nevada Division of Water Resources requiring 22.5% of water rights converted from agricultural use to mining be discounted. Consequently, less water will be pumped annually from the Quinn Valley than was available to agricultural users in previous years.

Also, groundwater pumping for Thacker Pass will occur more consistently over a 12-month period, rather than the seasonal pumping required for agricultural use. More consistent pumping throughout the year should lead to less seasonal drawdown of the area aquifer.

PIPELINE CONSTRUCTION AND QUALITY

The pipeline is designed and installed to meet all state and federal requirements.

The pipeline uses materials that are safe for potable water systems for public use or consumption; it’s primarily made of high-density polyethylene (HDPE) pipe and stainless-steel fittings and valves. The pipeline was constructed to National Sanitation Foundation (NSF 61) standards and installed so that it is safe for the public drinking water use, as specified by the Nevada Department of Environmental Protection (NDEP).

In the fall of 2023, the pipeline underwent eight hydrostatic tests which measure pressure vessels such as pipelines, plumbing, gas cylinders, boilers and fuel tanks for strength and leaks.

WATER RECYCLING AND MANAGEMENT

Once Thacker Pass is operational, water used in the processing and manufacturing of battery-grade lithium carbonate will be recycled and used repeatedly . Lithium Americas commissioned a study showing that every drop of water used in the processing plants will be reused as many as seven times before being evaporated to atmosphere. (For more information about our water recycling process, visit our Recycling and Reusing Process Water to Minimize Environmental Impacts blog.)

Water needs during construction will be significantly lower than the permitted water rights at approximately 900 AFA. During this time, unused water rights will be temporarily transferred to nearby farming operations to assist with crop production and we will provide water fill stations for local ranchers who lease the grazing allotments at Thacker Pass.

Lithium Americas is also working with the regional BLM Fire Program to support their water and infrastructure needs should a rangeland fire break out near Thacker Pass.

ENVIRONMENTAL STEWARDSHIP

We are committed to environmental sustainability, reducing our biodiversity impacts, protecting local species and natural ecosystems, and to integrating conservation into the design and life cycles of our project and operating activities.

For the pipeline project, we partnered with High Mark Construction to build concrete armor barriers to prevent erosion at two Crowley Creek crossings on our pipeline right-of-way in the Quinn Valley. Concrete has been placed on the creek sides, and concrete driveways have been installed across the tops of both crossings.

Per BLM standards with M3 Engineering and Technology, these concrete creek crossings are designed to survive projected 100-year storms, prevent erosion and preserve the original flow of water, while making it safer and more efficient to access the Quinn Valley wells.

Responsible reclamation is also a priority and we undertake efforts as soon reasonably possible. The pipeline has been buried below the surface and the path where the work occurred has been contoured to blend in with the surrounding area and seeded with native plant seeds to help return the area to its natural state. For more information on reclamation, visit our Planning for Closure Before Starting blog.